Continuous Plating

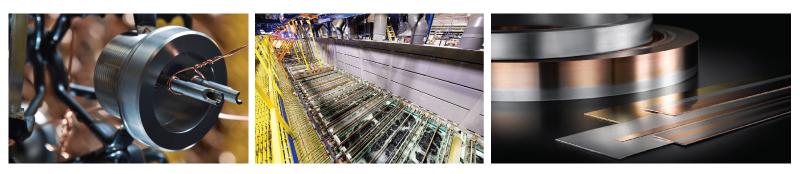

Continuous plating is a process where products are plated by running them through an assembly line one after another. The equipment includes pretreatment, plating equipment, and post-treatment. Continuous plating moves repeatedly and is essential to work pieces that require uniform coating, and geometry. These can include but not limit to strips, wires, and tubes.

To ensure even coating and efficient movement through the tanks, pieces of equipment are set up in a horizontal assembly line. This differs from the vertical assembly line found in barrel and rack plating. Unplated product can move along a steady line or loop generated by an accumulator at the end of the line to coil the product. The system is built to carry and transmit heavy current loads.

The process tanks are equipped with contact rollers and current contact. Each of them connect to an electrical power source in the plating system. They are transported by rollers and motors. The system is built to be two tiered system, with the tanks on the bottom and the cathode/anode roller on top. Sometimes wider strips need an auto guiding mechanism to ensure the tracking of the transition. The method is conserved a cheaper on than rack or barrel.

Whaley Products

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

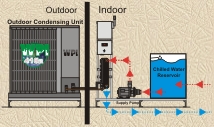

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |