Types of Plating Metals and there Properties

| Zinc

(Zn) |

Used on small parts, like fasteners, springs and hardware Coating is dull gray in color

Brightening agents can be added to add luster Coating is thin Usually used for interior or mildly corrosive conditions Hardness about 1/3 or ½ of steel |

||

| Tin

(Sn) |

Two types of categories- bright tin, or matte (solderable) tin

Bright Tin– high degree of luster- bus bars, terminals and switching components Matte Tin– can be used for alloys, is free from brighteners, Both must be heat sealed to ensure longevity

|

||

| Copper

(Su) |

Soft, ductile, lustrous, very high thermal and electrical conductivity

Used as an under plating to enhance adhesion, used to improve electrical properties, Improves corrosion resistant, impairs migration of elements into final plated cathode, Wide range of bright and matte |

||

| Nickel

(Ni) |

Electroless-

High Phosphorous– semi bright- matte appearance, nonmagnetic, solderable, high corrosion resistant Medium Phosphorus- semi bright- bright appearance, magnetic, good solderablity, moderate corrosion resistance |

Electrolytic-

very bright shine, satin appearance, full-dull matte luster, Slow to react in standard atmospheric environments Excellent corrosion performance, high melting point

|

|

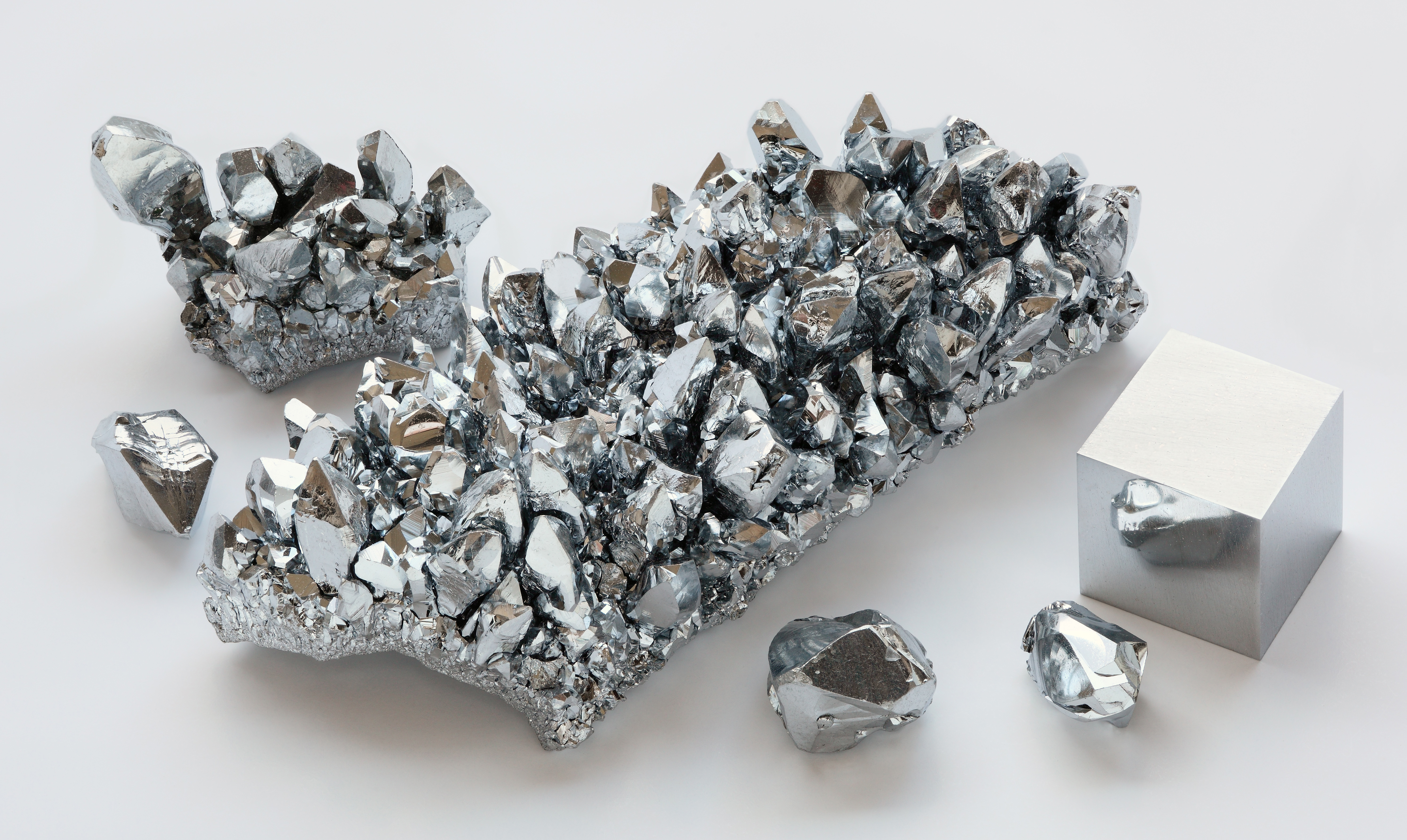

| Chromium

(Cr) |

Hard– heavy coating for wear resistance and purposes, items made of steel, or hardened steel, measured in thousandths of inch

|

Decorative– also called nickel-chrome plating,

Nickel must be plated first, then chrome Nickel is smoothness, corrosion resistance, reflective Bluish cast, protects Nickel from tarnish, |

|

| Gold

(Au) |

Exceptional solderablity, superb reflector of infrared radiation Does not oxidize

Hard Gold used for repeated sliding or connection wear ( female-male or sprung interconnects) Soft Gold highest cold purity, used for soldering, wire bonding and high temperatures, or high corrosion

|

||

| Silver

(Ag) |

Ductile Metal with white luster, Used for jewelry and utensils

Highest electrical and thermal conductivity, Tarnishes readily Highest optical reflectivity in visible range |

||

| Alloys

Zn-Fe, Zn-Co, Zn- Sn, Su-Sn, Sn-Zn, Sn-Co, |

Metallic properties, made up of two or more elements,

Coatings are made of plating two metals in the same cell, One of the combination of elements must be metal, Cannot be detected by human eye |

||